Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Introduction:

In the dynamic realm where technology meets design, aluminum honeycomb composite panels have emerged as a revolutionary material, transforming industries with their unique properties. This exploration delves deep into the multifaceted aspects of these panels, shedding light on their applications, advantages, manufacturing intricacies, and the innovative strides they've made across diverse industries.

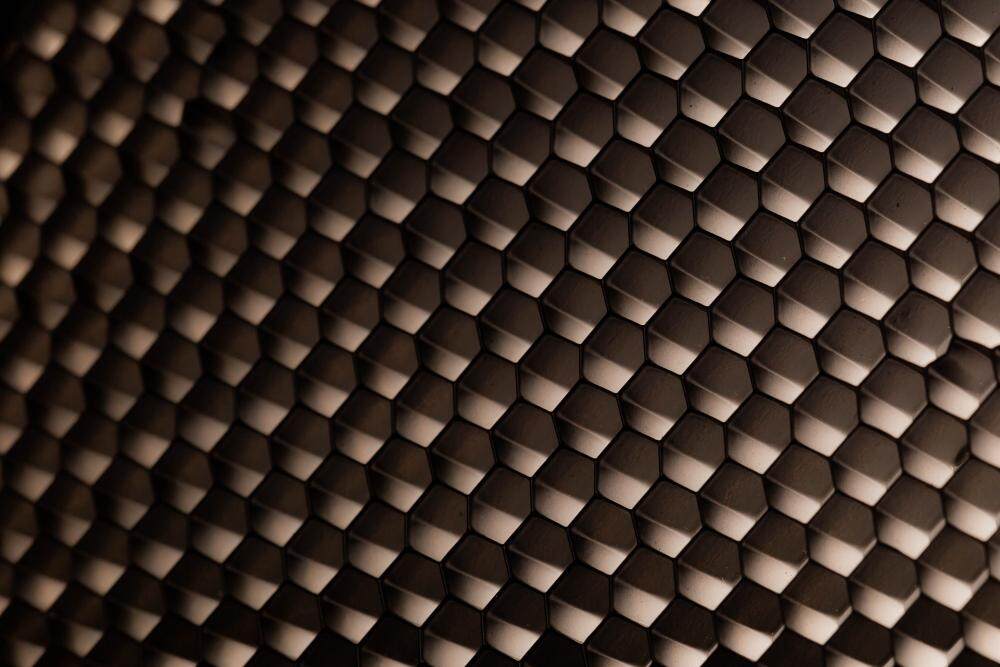

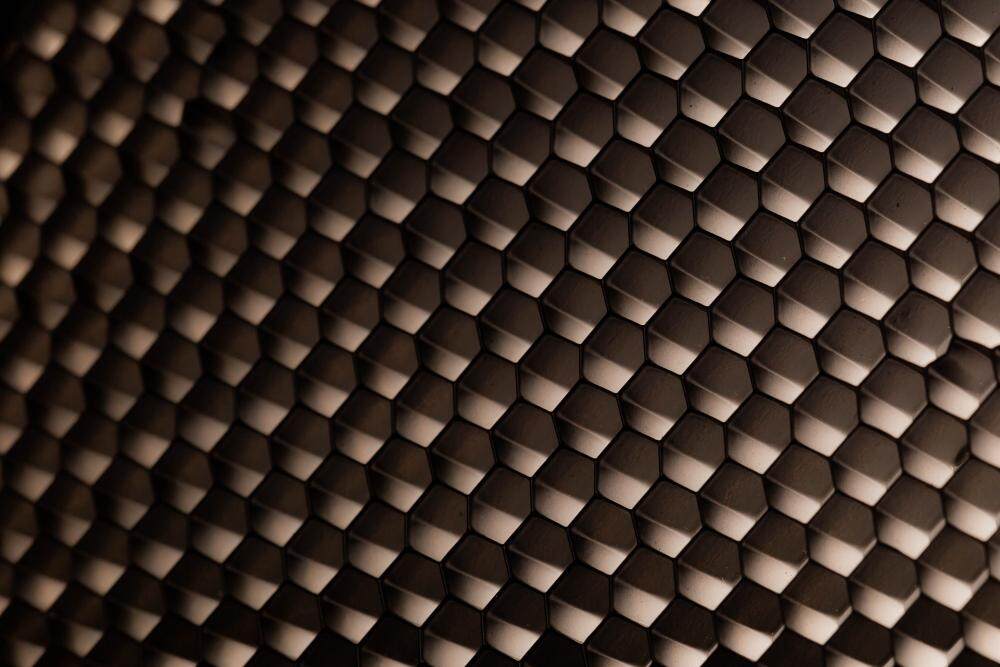

1. The Marvelous Structure of Aluminum Honeycomb Composite Panels:

The structural brilliance of aluminum honeycomb composite panels lies in their intricate design. Layers of aluminum sheets, bonded to a honeycomb core, create a composite that achieves unparalleled strength and rigidity while maintaining an impressively low weight. This cellular arrangement, inspired by nature's efficiency, not only enhances structural integrity but also contributes to the overall durability and flexibility of the panels.

2. Applications Across Industries:

The versatility of aluminum honeycomb composite panels extends across industries, making them a cornerstone in various sectors. From aviation, where their lightweight nature enhances fuel efficiency without compromising structural integrity, to the architectural realm, where they are increasingly chosen for modern, sustainable structures, these panels have redefined possibilities in diverse fields. Their application spectrum includes automotive, marine, and even artistic installations, showcasing their adaptability.

3. Advantages and Benefits:

Beyond their structural prowess, aluminum honeycomb composite panels offer a myriad of advantages. Their lightweight composition facilitates easy transportation and installation, making them a preferred choice in construction projects. Additionally, their corrosion resistance ensures longevity, even in challenging environmental conditions, contributing to cost-effectiveness and sustainability. The panels also exhibit excellent thermal insulation properties, adding another layer of functionality.

4. Manufacturing Precision:

The manufacturing process of aluminum honeycomb composite panels involves intricate precision and cutting-edge techniques. Layers of aluminum sheets are bonded to the honeycomb core with meticulous attention to detail, ensuring uniformity and high-quality standards. This precision not only guarantees the reliability of the panels but also opens avenues for innovative applications across various industries. Advanced manufacturing technologies contribute to precise panel dimensions and consistent quality.

5. Comparative Analysis with Traditional Materials:

A comprehensive comparative analysis underscores the superiority of aluminum honeycomb composite panels over traditional materials. Their lightweight nature not only reduces transportation costs but also minimizes the environmental impact associated with heavier alternatives. The panels represent a harmonious blend of strength and eco-friendliness, aligning with the growing emphasis on sustainable construction practices. Comparisons delve into aspects such as structural performance, cost-effectiveness, and environmental impact.

6. Design Flexibility and Customization:

The versatility of aluminum honeycomb composite panels extends to design flexibility and customization, making them a favorite among architects and designers. These panels offer a canvas for creative expression, allowing architects to create unique, aesthetically pleasing structures. The ability to customize dimensions, shapes, and finishes adds a layer of adaptability that aligns seamlessly with evolving design trends, giving designers unprecedented freedom.

7. Environmental Sustainability:

In an era focused on sustainable construction practices, aluminum honeycomb composite panels stand out as environmentally friendly. The panels' recyclability contributes to reducing the carbon footprint, aligning with global initiatives for green building materials. This intersection of strength and sustainability positions them as a frontrunner in eco-conscious projects where durability meets environmental responsibility. Life cycle assessments and environmental impact studies further support their green credentials.

8. Real-world Applications: Case Studies:

Examining real-world applications through detailed case studies provides tangible evidence of the practical benefits of aluminum honeycomb composite panels. From high-rise buildings requiring structural integrity to cutting-edge aircraft demanding lightweight solutions, these panels have proven their mettle in diverse environments. The case studies offer insights into the panels' reliability, adaptability, and positive impact on the efficiency of projects. In-depth analyses showcase specific project challenges and how the panels addressed them effectively.

9. Future Trends and Innovations:

The journey of aluminum honeycomb composite panels doesn't end here; it's an evolving narrative with futuristic trends and innovations. Researchers are actively exploring advanced materials, such as hybrid composites, and manufacturing techniques to further enhance the panels' properties. The integration of smart technologies, such as sensor-equipped panels for real-time monitoring and advanced coatings for enhanced durability, promises an exciting future for these panels at the forefront of material innovation. Collaborations between research institutions, manufacturers, and designers are shaping the future landscape.

10. Maintenance for Longevity:

Ensuring the longevity of structures using aluminum honeycomb composite panels involves a proactive approach to maintenance. Comprehensive guidelines, including cleaning procedures, routine inspections, and considerations for repairs, contribute to the panels' extended lifespan. This meticulous care aligns with the long-term benefits of investing in advanced construction materials, emphasizing durability, sustained performance, and the importance of regular inspections for continued safety.

Conclusion:

As we conclude our exploration into the world of aluminum honeycomb composite panels, it becomes evident that these panels represent more than just a construction material. They embody a harmonious blend of engineering precision, environmental consciousness, and design versatility. Whether soaring through the skies in aerospace applications or shaping the skylines in architectural endeavors, aluminum honeycomb composite panels stand as a testament to human ingenuity, promising a sustainable and resilient future across diverse domains. The ongoing advancements and collaborative efforts ensure that their story continues to unfold, with each chapter revealing new possibilities and innovations.